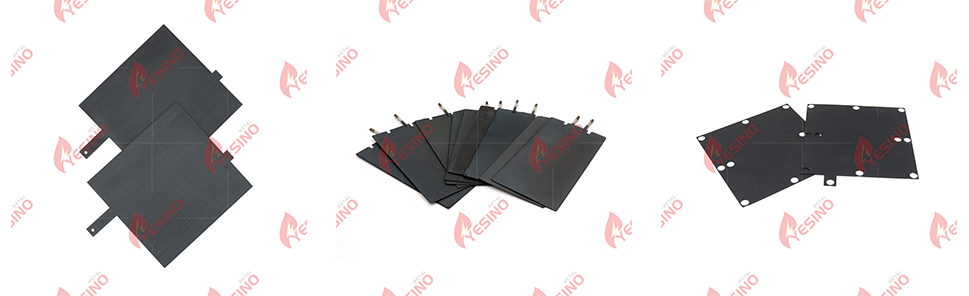

MMO anode plates (Mixed Metal Oxide Anode Plates) play a vital role in sodium hypochlorite generators and are mainly used in the electrolysis process to generate sodium hypochlorite solution. Sodium hypochlorite generators utilize the principle of electrolysis of brine (sodium chloride solution) to produce sodium hypochlorite (NaOCl) by electrolyzing water and salt with an applied electric current.The MMO anode plate, as a key component in this electrolysis system, assumes the role of anode in the electrolysis reaction.

It can stabilize the electrolysis reaction, and the mixed metal oxide coating on the surface of the MMO anode plate has high catalytic activity, which can effectively promote the electrolysis of sodium chloride to produce chlorine gas, and at the same time prevent the plate surface from oxidation, so as to improve the efficiency of the electrolysis.The MMO coating consists of ruthenium, iridium, and other precious metal oxides, which have very high corrosion resistance, and it is able to work for a long time in the harsh environment of brine and chlorine without corrosion, so as to prolong the service life of the anode. service life. Since MMO anode plate has low overpotential (the lowest potential required for oxidation reaction), it can maintain efficient electrolysis reaction with low power consumption and reduce energy consumption.MMO anode plate is able to control the generation of by-products during electrolysis, such as reducing the generation of oxygen, and improving the production of chlorine gas and sodium hypochlorite. After a long period of use, the coating of MMO anode can be regenerated by re-coating with metal oxides if there is any degradation in performance, which greatly extends the life cycle of the anode and reduces operating costs.

MMO anode plate is the core component in the electrolysis process in sodium hypochlorite generator, which greatly enhances the production capacity and economy of the equipment through its high efficiency, durability and energy-saving characteristics.

Brief introduction:

| Substrate | Titanium Grade 1, Titanium Grade 2 |

| Coating | 1. Ruthenium-Titanium Anode 2. Ruthenium-Iridium Titanium Anode 3. Iridium-Tantalum Titanium Anode 4. Iridium-Tantalum-Tin Titanium Anode 5. Iridium-Platinum Titanium Anode 6. Platinum Titanium Anode 7. Lead dioxide Titanium Anode |

| Coating Thickness | 6~12micron--Mixed precious metal oxide coating

0.5~5micron--Platinum coating |

| Shape | Plate/Mesh/Tube/Rod/Wire/Disc or Customized as the design drawing |

| Technology | Sand blasting, Acid Washing, Coating Brushing, High Temperature Sintering, Annealing |

| Current density | < 20000 A/M2 |

| PH value | 1—14 |

| Content of Florin Ions | <50mg/L |

| Enhanced life | 40k mA/M2, 1 mol/L H2SO4, h=1200 h |

| Application | 1. Sewage Treatment

2. Cathode Protection

3. Noble Metal Plating (silver, gold)

4. Sea Water Antifouling

5. Testing Electrode

6. Electrolytic Synthesis Of Organic

7. Electroplating Industry

8. Electrodialysis

9. Electrolytic Water etc |

| Remark | 1. Titanium anode also called MMO anode,DSA & Insoluble anode

2. Cathode also be provide

3. Small sample order available |

.

Other Anode:

Through years of development, Yesino has become a comprehensive manufacturer and trader of titanium products. Currently the products we can provide are:Titanium Plate, Titanium Sheet, Titanium Round Bar, Titanium Forging, Titanium Tube , Titanium Powder and MMO titanium anode