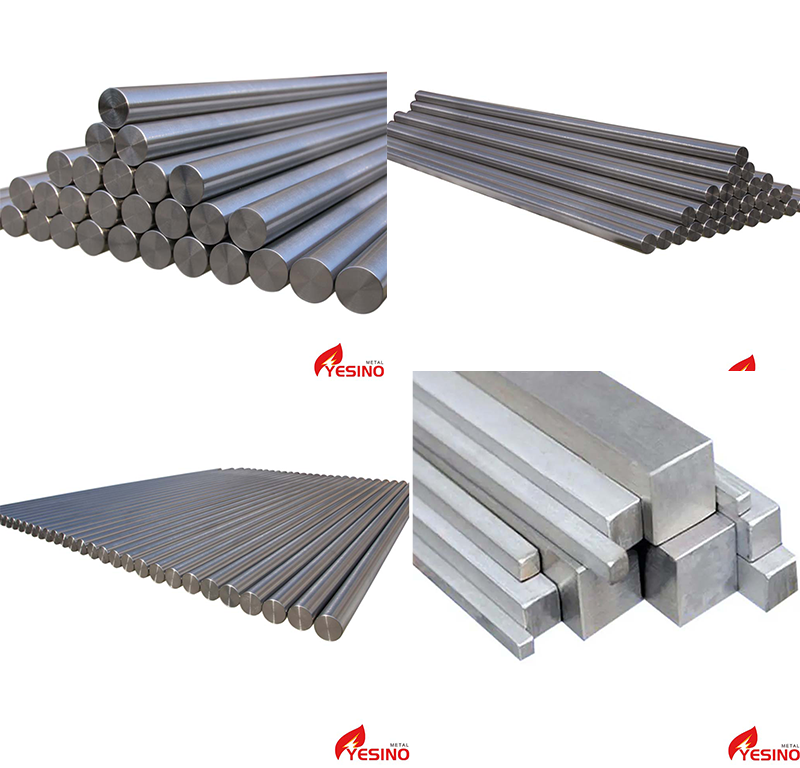

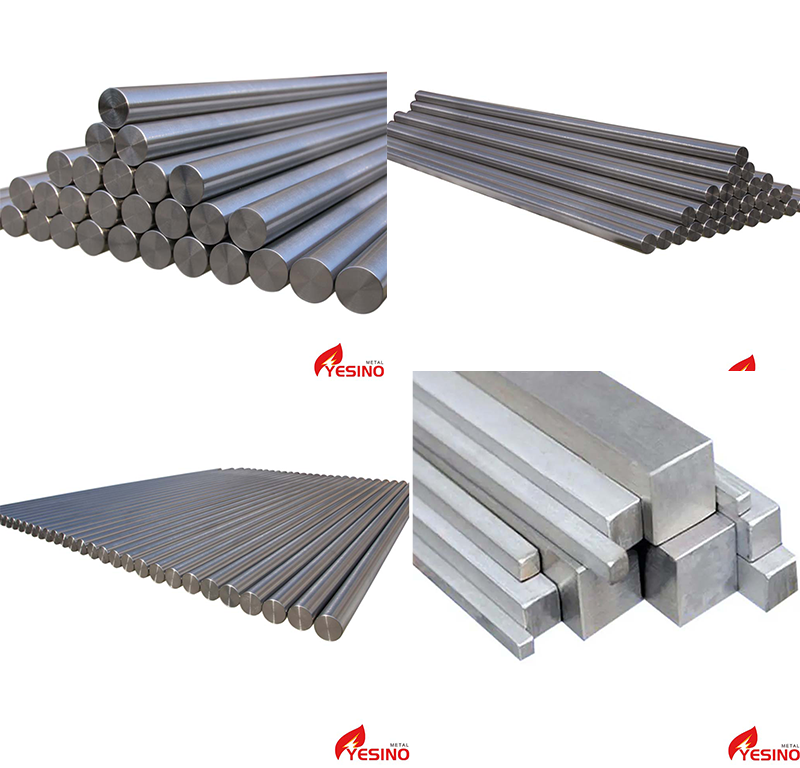

The AMS standard 6246 titanium round bar is a high-quality and reliable product that meets the stringent requirements of various industries. This round bar is manufactured using advanced techniques and adheres to the strict specifications set by the Aerospace Material Specification (AMS) standards and aerospace application Titanium

With its exceptional strength-to-weight ratio, corrosion resistance, and excellent heat resistance properties, this titanium round bar is widely used in aerospace, automotive, medical, and marine applications. It provides structural integrity while reducing overall weight in aircraft components such as landing gear assemblies, engine mounts, and airframe structures.

In addition to its mechanical properties, this titanium round bar also offers biocompatibility features that make it suitable for medical implants like orthopedic devices or dental implants. Its non-magnetic nature makes it ideal for use in MRI machines where magnetic interference must be minimized.

Furthermore, the AMS titanium round bar can withstand extreme temperatures ranging from sub-zero conditions to high-temperature environments without compromising its performance. This makes it an excellent choice for applications exposed to harsh weather conditions or elevated operating temperatures.

Manufacturers ensure strict quality control measures during production to guarantee consistent dimensions and surface finish of each titanium round bar. These bars are available in various sizes and lengths according to customer requirements.

Overall, the AMS standard 6246 Titanium Bar stands as a testament to technological advancements in material science. Its versatility across multiple industries showcases its reliability and durability under demanding conditions. Whether used in aerospace engineering or medical innovations, this titanium round bar continues to play a vital role in advancing technology worldwide.