The AMS 4981 Titanium Forging for Aerospace Application is a highly specialized and crucial component in the aerospace industry. Titanium forgings are widely used in aircraft manufacturing due to their exceptional strength-to-weight ratio, corrosion resistance, and high temperature capabilities.

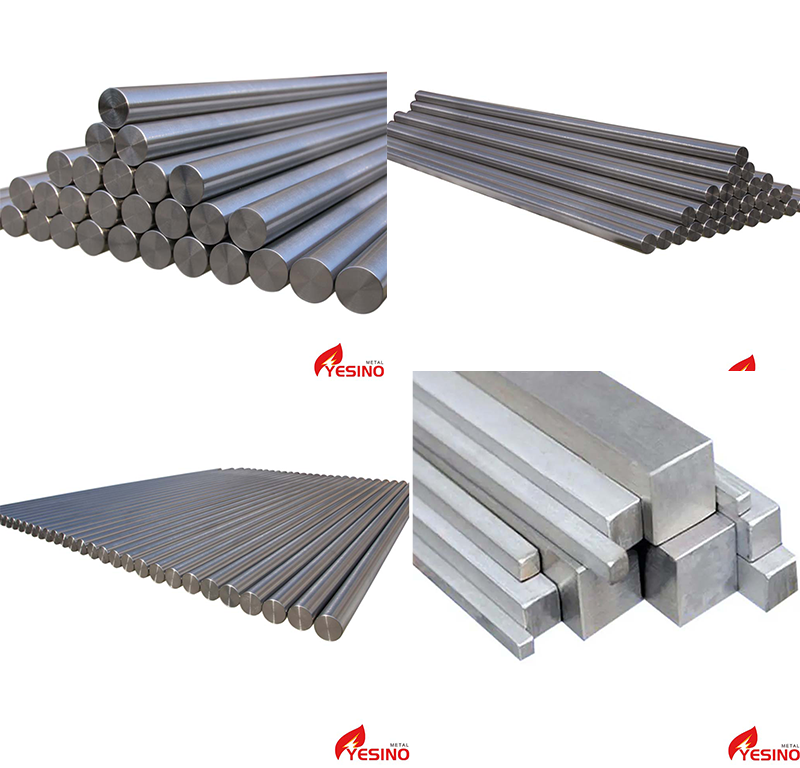

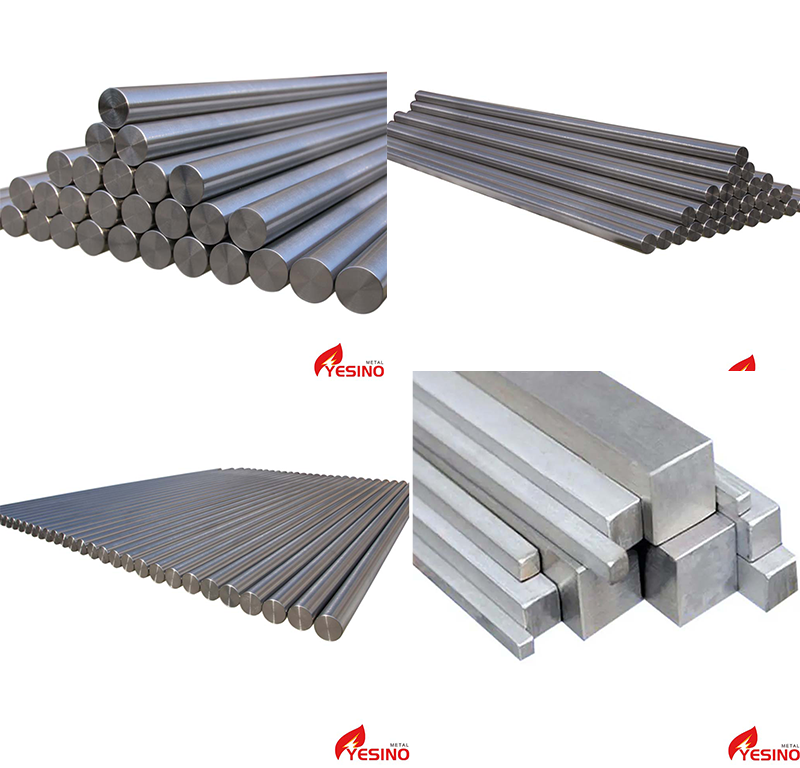

This specific titanium forging material, designated as AMS 4981, meets stringent quality standards set by the aerospace industry. It undergoes a rigorous manufacturing process that involves heating the titanium alloy to its plastic deformation temperature and then applying pressure to shape it into the desired form. This forging technique ensures superior mechanical properties and structural integrity of the final product.

In titanium alloy aerospace applications, such as aircraft engines, landing gears, airframes, and other critical components, AMS 4981 titanium forgings play a vital role in ensuring safety and reliability. The lightweight nature of titanium allows for fuel efficiency while maintaining structural integrity under extreme conditions.

Moreover, this particular grade of titanium forging exhibits excellent resistance to fatigue crack growth and stress corrosion cracking. These properties make it an ideal choice for parts subjected to high-stress environments encountered during flight operations.

The use of AMS 4981 titanium 6246 forgings also contributes to reducing maintenance costs in the long run. Their durability minimizes wear-and-tear issues commonly associated with heavy usage over time. Additionally, their resistance to chemical attacks from fuels or hydraulic fluids further enhances their longevity.