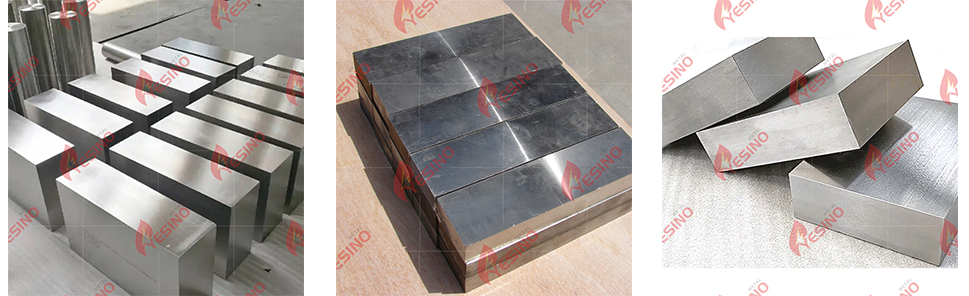

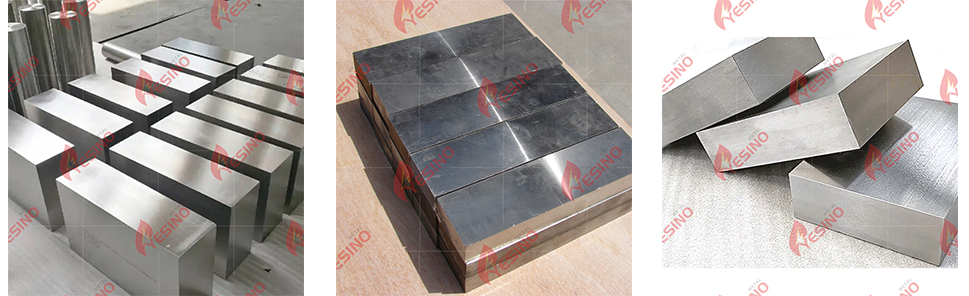

Yesino Metal has been dedicated to continuously improving its production and processing capabilities since 2008. With a strong focus on customer satisfaction, we have consistently analyzed and learned from each customer-designed drawing order, allowing us to accumulate valuable experience in the field of forging and superfinishing.

Our state-of-the-art facilities play a crucial role in our success. Equipped with advanced machinery such as 2000 tons and 3500 tons free forging hydraulic presses, as well as full hydraulic manipulators and CNC centers, we are able to meet the diverse needs of our customers with precision and efficiency.

In addition to our cutting-edge equipment, Yesino Metal takes pride in its team of highly skilled professionals. Comprising 14 R&D experts who possess extensive knowledge in the industry, we constantly strive for innovation and excellence. Their expertise enables us to deliver superior quality products that exceed expectations.

With an annual forging production and processing capacity of up to 40,000 tons, Yesino Metal is well-positioned to handle large-scale projects while maintaining strict adherence to quality standards. Our commitment to continuous improvement ensures that we stay at the forefront of technological advancements within the industry.

As a result of our dedication and hard work over the years, Yesino Metal has established itself as one of the leading forging and superfinishing factories in the market today. We take great pride in serving our customers with top-notch products that meet their specific requirements while providing exceptional value for their investment.

Moving forward, Yesino Metal will continue its pursuit of excellence by investing in research and development initiatives aimed at further enhancing our capabilities. We remain committed to delivering outstanding results for every customer while upholding our reputation as a reliable partner in the field of metal manufacturing.

Standard: ASTM B381 AMS 4928 ASTM F67,ASTM F136

Materials: Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23

Dimension is Customized, according drawings

Specification: Dia:50-1500 mm Thickness : 35-500 mm