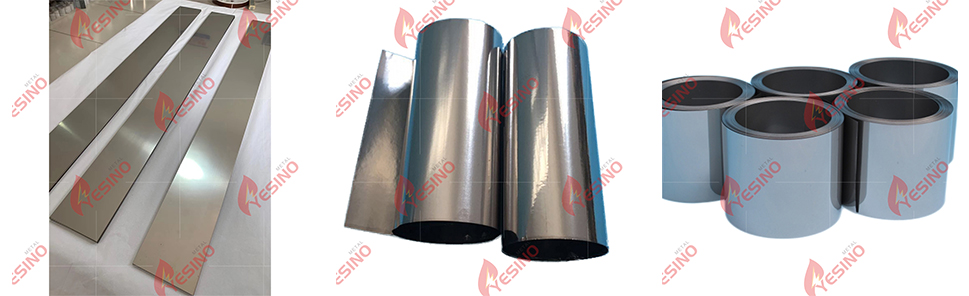

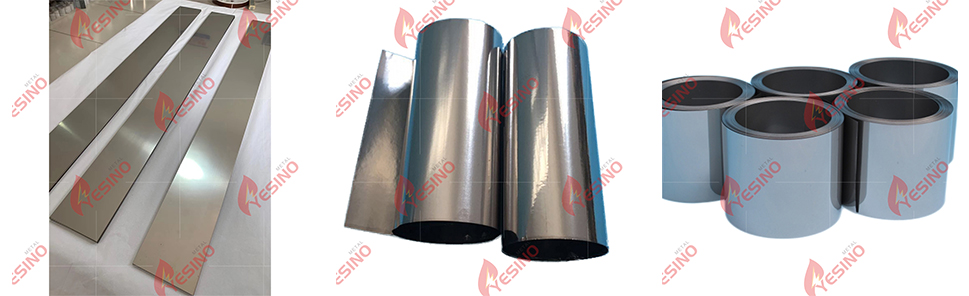

Grade 2 Titanium Foil is a versatile material that can be used in both final products and finishing. It is easily molded and adheres well to pre-existing forms, providing added protection, strength, and resistance to corrosive materials and environmental wear. Pure Titanium foil is commonly available in rolled coils, which many manufacturers prefer due to its regulated nature and predictable shipping and processing requirements. Common processes for creating titanium foils include continuous cast stripping and rolling.

To create foil with these varying thicknesses, manufacturers typically use a series of presses and rollers to thin out sheets or strips of titanium until they reach the desired level of thinness. This process requires precision and expertise, as even small variations in thickness can have significant impacts on how well the finished product performs.

Summary:

- Titanium Foil is versatile for use in final products or finishing.

- Titanium foil sheet provides added protection, strength, & resistance.

- Rolled coil form of titanium foil preferred by manufacturers.

- Common processes for creating titanium foils are continuous cast stripping & rolling.