Flexible and Durable Titanium Sheet Products for Industrial

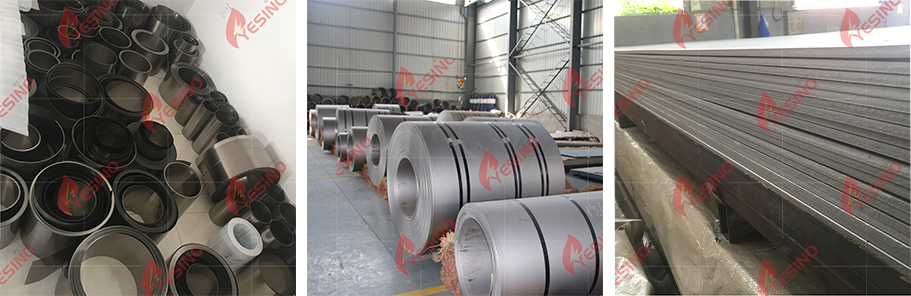

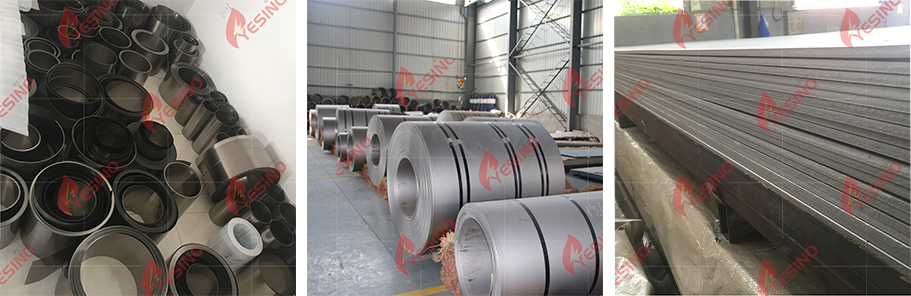

Production of Titanium Sheet Titanium Alloy Sheet are typically produced using a process known as cold rolling, which involves passing a titanium ingot through a series of rollers to reduce its thickness. The resulting sheet is then annealed to relieve any residual stresses and improve its ductility. Titanium sheets can be further processed using techniques such as cutting, welding, and forming to create components that meet specific design requirements. The production of titanium sheets is a complex process that requires specialized knowledge and equipment, and as such, they are typically more expensive than other metals.

Grades of Titanium Sheets Titanium sheets come in several different grades, each with its own set of properties and characteristics. The most common grades are commercially pure titanium (CP) grades 1 to 4, which have varying levels of oxygen and iron content, and offer good corrosion resistance and formability. Other grades, such as Ti-6Al-4V and Ti-6Al-4V ELI, are alloys that contain aluminum and vanadium, and offer higher strength and fatigue resistance, making them ideal for high-performance applications.